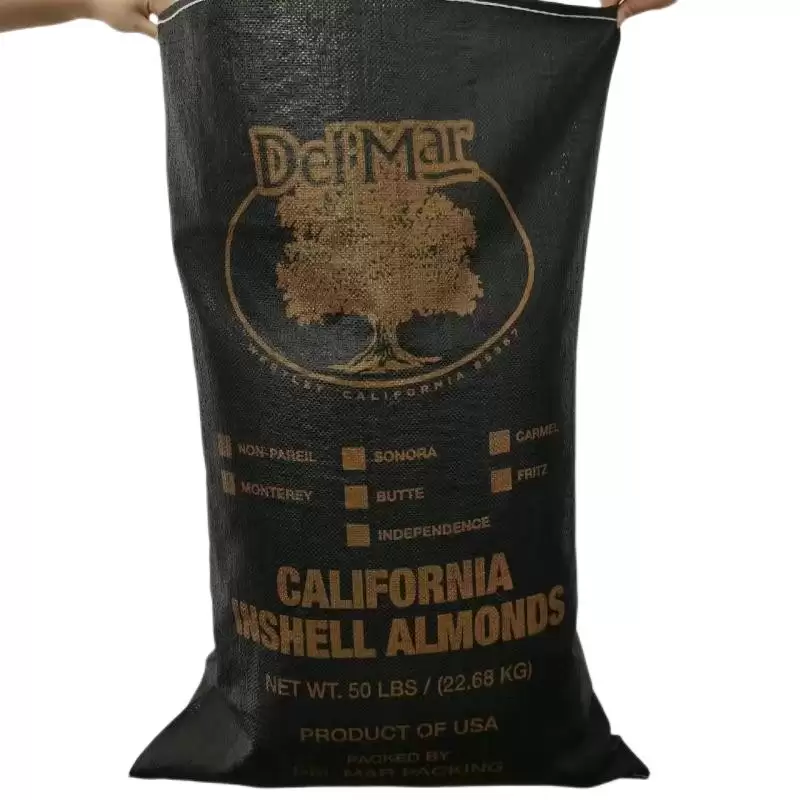

Printed woven bags are designed to print patterns on regular woven bags according to customer requirements. Compared with ordinary woven bags, printed woven bags not only know the products packaged in the bag faster, but also have a beautiful appearance that will leave a deep impression on customers.

In addition, printed woven bags have advantages such as moisture resistance, high temperature resistance, mold resistance, resistance to slipping, convenient stacking, slight breathability, reduced damage, flat surface, good smoothness, low price, good environmental friendliness, reusability, novelty and aesthetics

The production process of printed woven bags

1)The first step is to create a printing plate from the text and images that need to be printed on the plastic woven bag, and install this printing plate on the woven bag printing machine.

2)The second step is to add ink to the woven bag printing machine so that it can evenly cover the printing plate with text and images.

3)The third step is to use a woven bag printing machine to print the text and images on the printing plate onto the plastic woven bag.

Announcements:

1.Pay attention to the load-bearing capacity of pp woven bags.

2.Do not drag them on the ground to prevent soil from entering the interior of the woven bag or causing the bag threads to crack.

3. When using pp woven bags to package items for long-distance transportation, it is necessary to cover the woven bags with some waterproof or moisture-proof cloth to avoid direct sunlight or rainwater corrosion.

4. pp woven bags should avoid contact with chemicals such as acid, alcohol, gasoline, etc.