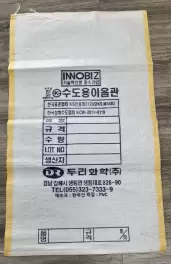

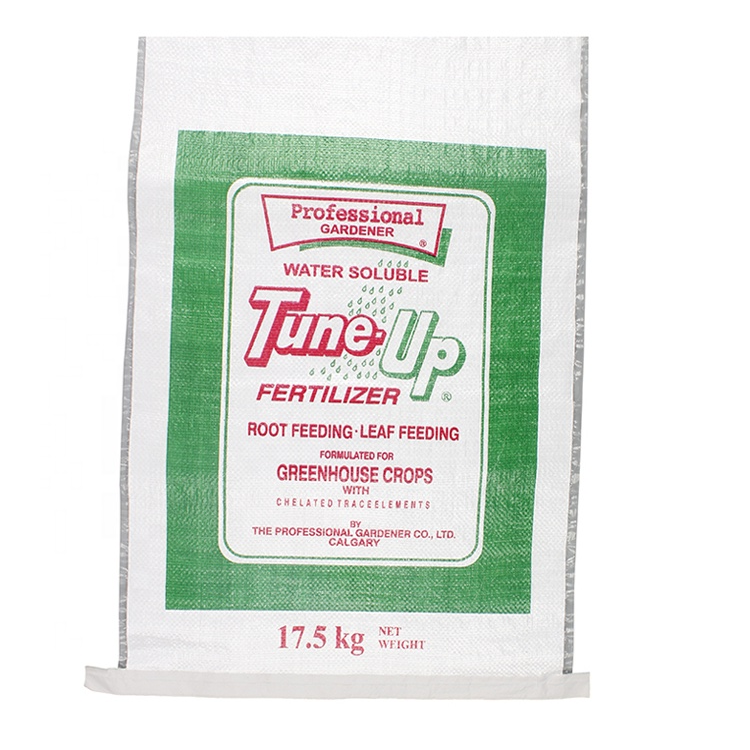

Woven bags, also known as snake skin bags. It is a type of plastic used for packaging, and its raw materials are generally various chemical plastic materials such as polyethylene and polypropylene.

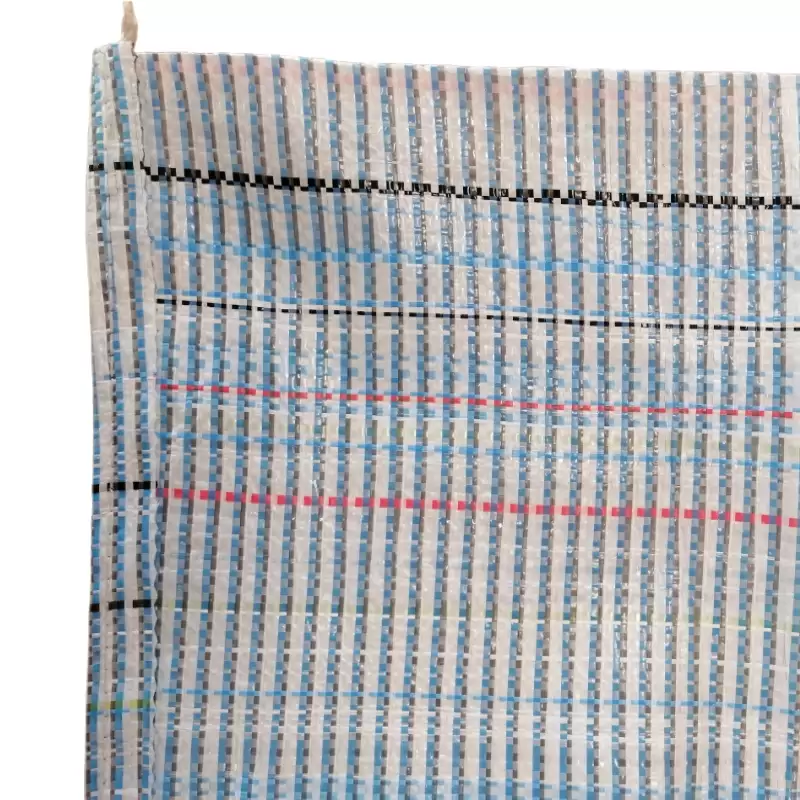

Plastic woven bags are made of narrow strips of plastic film with a certain width, or by weaving plastic flat strips with high strength and low elongation using hot stretching method. Plastic woven bags have much higher strength than plastic film bags, are not easily deformed, and have good impact resistance. At the same time, the surface of the woven bag has woven patterns, which greatly improves its anti slip performance and facilitates stacking during storage.

Advantages:

1)Light weight

2)High fracture strength

3)Good chemical corrosion resistance

4)Good wear resistance

5)Good electrical insulation

6)Environmental resistance

Applications:

1)Packaging bags for industrial and agricultural products

2)Food packaging bags

3)Tourism and transportation industry

4)Engineering materials

5)Flood control materials

Announcements:

1)Avoid loading items that exceed the carrying capacity to avoid damage to woven bags or inability to handle them.

2)Avoid dragging directly on the ground, as the conflict between the woven bag and the ground not only brings soil from the ground into the interior of the woven bag, but also may cause the bag silk to crack, accelerating the damage speed of the woven bag.

3)Avoid direct sunlight and rainwater corrosion to accelerate the aging rate of the product.

4)Avoid contact with chemicals such as acid, alcohol, gasoline, etc. to maintain their flexible texture and original color.