China laminated sack factory

laminated sacks, durable packaging, sustainable packaging, eco-friendly

Free samples we can offer

-

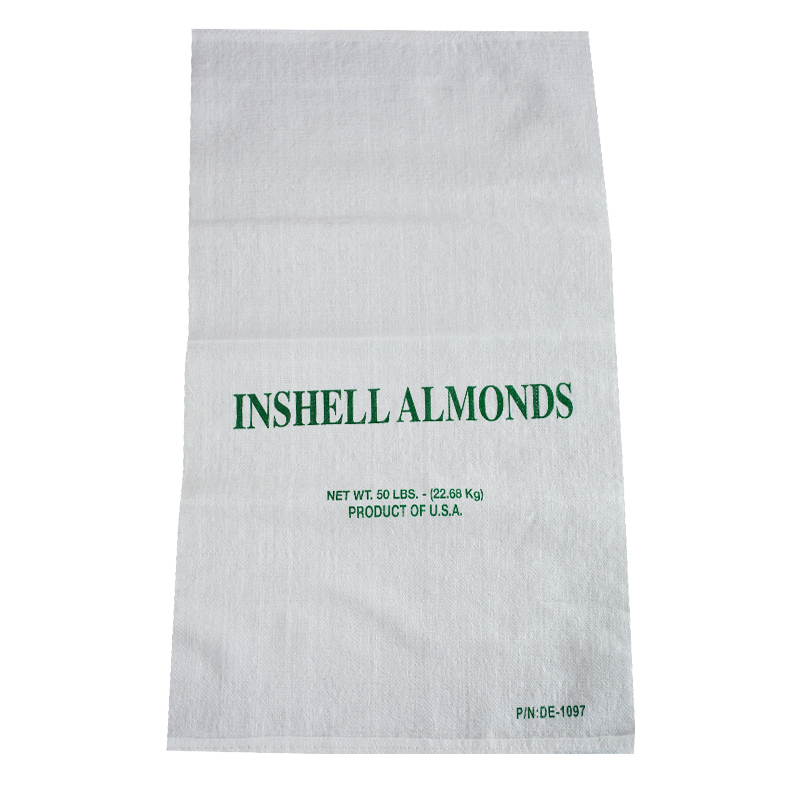

Sample1

size

-

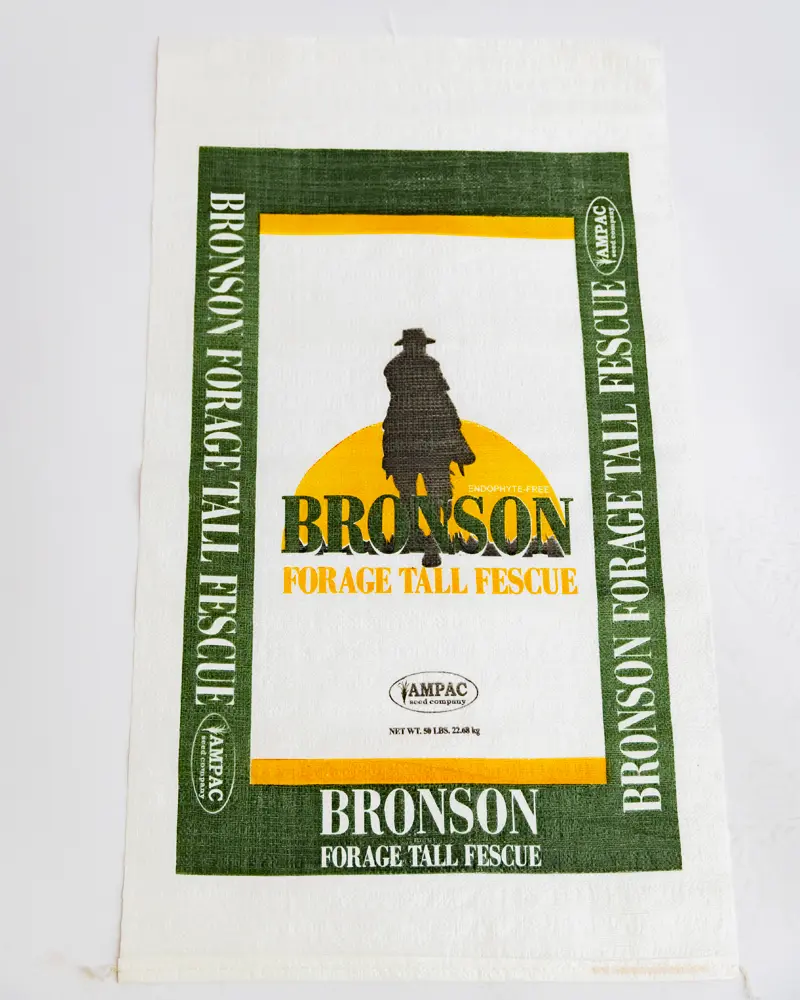

Sample2

size

-

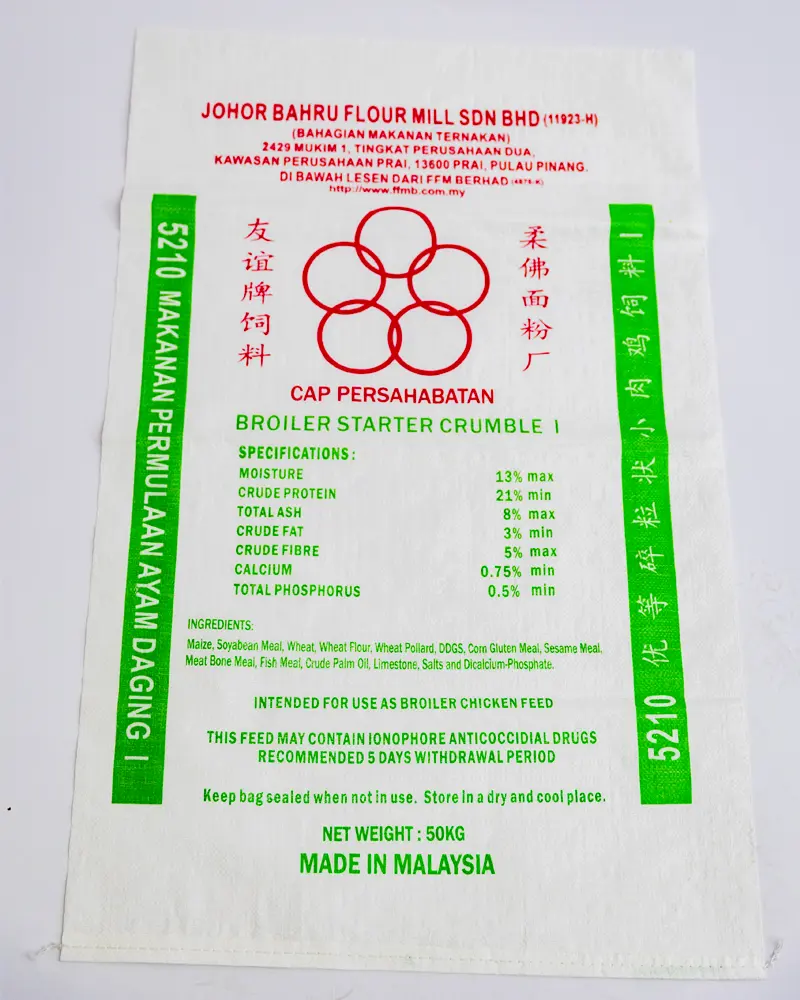

Sample3

size

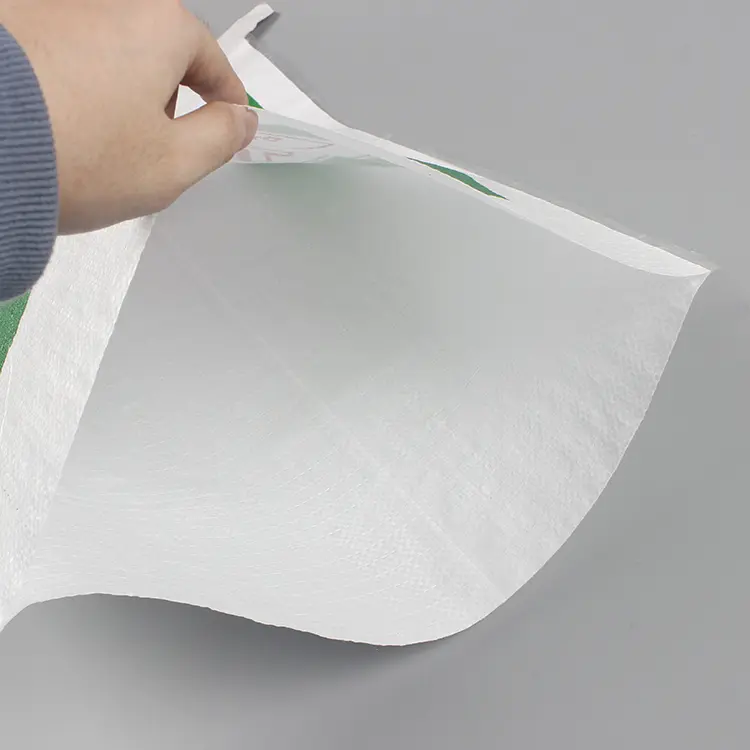

Detail

Laminated Sack: The Ultimate Solution for Durable and Sustainable Packaging

We will supply best quality, the most market competitive price, for every new and old customers with the most perfect green services.

Introduction:

Packaging plays a crucial role in various industries, ensuring the safe transportation and storage of goods. However, the environmental impact of traditional packaging materials such as plastic and paper bags has raised concerns in recent years. Laminated sacks have emerged as a sustainable and durable alternative, providing a solution that meets the demands of both businesses and environmentally-conscious consumers.

1. What are Laminated Sacks?

Laminated sacks, also known as laminated woven bags, are made by laminating a layer of plastic film to a woven fabric bag. This lamination process enhances the strength and durability of the sack while providing it with water resistance and protection against UV rays. The woven fabric used in these sacks is typically made of polypropylene, a highly versatile and recyclable material.

2. Durability that Lasts:

One of the key advantages of laminated sacks is their exceptional durability. The lamination process strengthens the woven fabric, making it resistant to tearing and puncturing. This ensures that the contents of the sack remain secure during transportation, storage, and handling. With reusable capabilities, laminated sacks offer a cost-effective and long-lasting packaging solution.

3. Enhanced Efficiency:

Laminated sacks offer improved efficiency in packaging due to their lightweight nature. Compared to traditional packaging materials, they are lighter and require less space, resulting in reduced shipping costs. The lightweight design also makes it easier for workers to handle and stack the sacks, enhancing overall operational efficiency.

4. Eco-Friendly Solution:

In an era where sustainability is paramount, laminated sacks stand out as an eco-friendly solution. The laminating process extends the lifespan of the packaging, reducing the need for frequent replacements. Additionally, the use of recyclable materials such as polypropylene ensures that these sacks can be recycled at the end of their life cycle. This significantly reduces plastic waste and supports efforts to create a more sustainable future.

5. Versatility:

Laminated sacks are available in various sizes and shapes to accommodate different products and industries. They can be customized with printed designs, logos, and labeling, providing businesses with a branding opportunity. Furthermore, the water resistance and UV protection provided by the lamination process make these sacks suitable for a wide range of applications, including agriculture, construction, and pharmaceutical industries.

6. Cost-Effective Option:

Laminated sacks provide a cost-effective packaging solution for businesses. The durability and reusability of these sacks mean that companies can save on frequent replacements. Moreover, their lightweight design helps reduce transportation costs, making them a financially viable choice for businesses of all sizes.

Conclusion:

Laminated sacks offer a perfect combination of durability, sustainability, and cost-effectiveness, making them the ultimate solution for packaging needs. Whether it's protecting goods during transportation or reducing the environmental impact of packaging, laminated sacks tick all the boxes. Embracing this sustainable and effective packaging option is a step toward building a greener and more responsible future.

Really should any of these items be of interest to you, please let us know. We will be pleased to give you a quotation upon receipt of one's detailed specifications. We've our personal specialist R&D enginners to meet any of the requriements, We look forward to receiving your enquires soon and hope to have the chance to work together with you inside the future. Welcome to take a look at our organization.