What are Bopp Bags?

Bopp (Biaxially Oriented Polypropylene) bags are made from a thin film of polypropylene that is stretched in both directions, resulting in a material that is strong, transparent, and resistant to moisture. Bopp bags are commonly used for packaging products such as snacks, confectionery items, spices, and other food items. These bags are also used for packaging garments, textiles, and other non-food items.

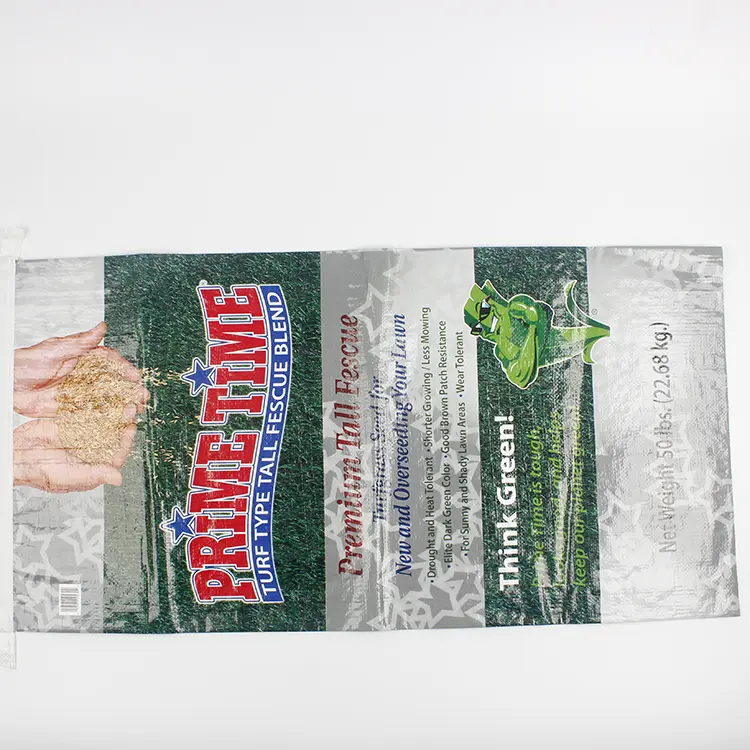

Bopp bags come in a variety of sizes and thicknesses and can be printed on using high-quality printing techniques. These bags are also available in different finishes such as matte, glossy, and metallic.

Differences between PP Bags and Bopp Bags

1.Composition

PP bags are made from polypropylene, a thermoplastic polymer that is known for its strength and durability. This material is commonly used in a wide range of applications, including packaging, textiles, and automotive parts.

BOPP bags, on the other hand, are made from biaxially-oriented polypropylene (BOPP), which is a type of polypropylene that has been stretched in two directions to create a stronger, more durable material. BOPP is commonly used in packaging materials because of its high clarity, stiffness, and resistance to moisture.

3.Appearance

PP bags and BOPP bags have different appearances. PP bags are typically opaque and have a matte finish. They can be printed with custom designs and logos, but the printing is not as clear or vibrant as it is on BOPP bags.

BOPP bags, on the other hand, are transparent or translucent and have a glossy finish. They are often printed with high-quality graphics and logos that are clear and vibrant. This makes them an attractive option for products that require high-quality packaging.

3.Strength and Durability

Both PP bags and BOPP bags are strong and durable, but BOPP bags are generally considered to be stronger and more durable than PP bags. This is because BOPP has been stretched in two directions, which creates a material that is more resistant to tearing and punctures.

BOPP bags also have better moisture resistance than PP bags. This makes them a better option for products that need to be protected from moisture, such as food products or electronic components.

4.Cost

PP bags are generally less expensive than BOPP bags. This is because PP is a more common material that is easier to manufacture than BOPP. However, the cost difference may not be significant for small quantities of bags.

5.Printing

Both PP bags and Bopp bags can be printed on using high-quality printing techniques. However, Bopp bags offer better printing quality due to their smooth surface.

6.Applications:

PP bags are commonly used for packaging dry goods while Bopp bags are commonly used for packaging food items such as snacks and confectionery items.

Conclusion

In conclusion, both PP bags and Bopp bags have their own unique set of properties and applications. While PP bags are more durable and versatile, Bopp bags offer better transparency and moisture resistance. When choosing between the two, it is important to consider the specific needs of your product and choose the option that best meets those needs.