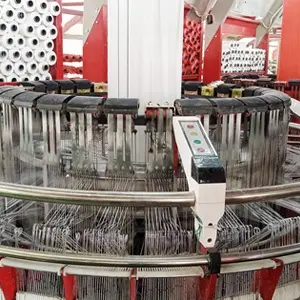

Alamun fasaha na tsarin saƙa

- Saukan Samu

Yaran da aka saka yana nufin yawan yaƙin da Wuffiyar yarns a cikin 100mm x 100mm m masana'anta. Ka'idojin ƙasa suna bayyana haƙurin da aka yi amfani da su, yawan mashin da aka yi amfani da su shine 36 × 40 / 10cm, 48/ 10cm, 48 × 48 / 10cm.

- Ingancin kowane yanki na yanki na masana'anta

Weight na kowane yanki naúrar yanki na mayafin mayu an bayyana shi a cikin murabba'in na hancin, wanda shine muhimmiyar nuna alamar fasaha ta fashin baya. Hankali a kowace murabba'in mita musamman ya dogara da warp da walwala da kauri daga cikin filayen lebur kuma babban bangare ne na ikon mallaka don masana'anta.

- Saka magunguna masu lafiyayyu

Don masana'anta, za su iya jure wa yaƙin da kuma gafartawa na hanyoyin biyu na kayan raɗɗen, ya ce, Warf da ke ɗauka.

- Nisa

Faɗin da aka saka iri-iri da yawa kai tsaye yana shafar tsarin yin jaka. Ga mayafin silinda, nisa yana nuna ta hanyar yakin da aka nada; Yakin da aka nada daidai yake da rabin kewayen.

- Runduna

Pp lebur siliki saka masana'anta, m, mai gadi da kashewa;

HDPE lebur siliki da aka saƙa, lubricated da ba mai yawa ba;

Additionarin calcium Masterbatch zuwa PP For Yarn ya ba shi tabbatacce; Additionarin ƙarancin HDPE zuwa PP ya sa ya fi laushi.

Idan filayen lebur ya zama kunkuntar, saƙa zai zama lebur da taushi ga taɓawa; Idan filayen lebur yana da faɗi, masu saƙa za su sami ƙarin filasiku masu yawa da jin daɗi.

A cikin tsarin samarwa naPP da aka saka jakar, Rabo na albarkatun kasa shine tabbatar da cewa samfurin da suka cancanta, musamman idan ya zo ga samfuran abinci, kayan abinci ba zai iya ƙara kayan da aka sake sarrafawa ba; zane shine mahaɗan mafi mahimmancin haɗin; Weaving, bugu da dinki wani muhimmiyar garantin kayan adon kayan abinci, musamman ga samfuran abinci, abubuwan da aka buga sun fi girma.

Duk cikin tsarin samarwa, sigogi da alamomin kowane tsari suna da hanyar haɗi kai tsaye zuwa tasirin ingancin samfurin. Nazarin tasirin kowane sigar fasaha da nuna alama akan ingancin samfurin zai iya inganta haɓaka, tabbatar da ingancin samfuri da haɓaka gasa ta masana'antu.