Materials Used in FIBC Bag Production

The production of FIBC bags begins with the selection of high-quality raw materials. The primary components used in manufacturing FIBC bags include:

1. Polypropylene (PP) or Polyethylene (PE) Fabric: The main body of the FIBC bag is typically made from woven polypropylene or polyethylene fabric. These materials are chosen for their strength, durability, and resistance to tearing and puncturing.

2. UV Stabilizers: To protect the FIBC bags from degradation caused by exposure to sunlight, UV stabilizers are added to the fabric during the manufacturing process.

3. Lamination: Some FIBC bags may feature a laminated coating to provide additional protection against moisture and contamination.

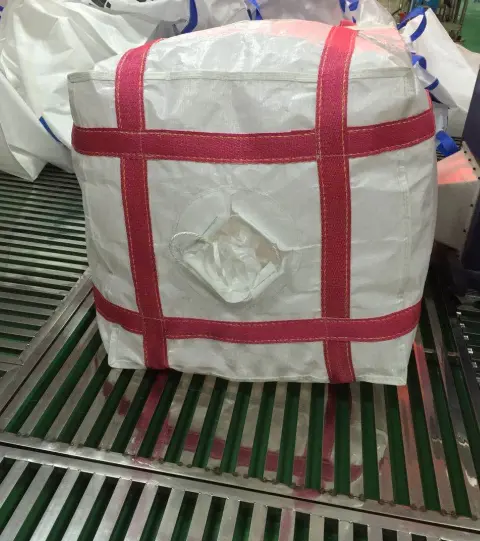

4. Filling and Discharge Spouts: These components are often made from polypropylene fabric and are designed to facilitate the filling and emptying of the FIBC bags.

Production Process of FIBC Bags

The manufacturing process of FIBC bags involves several key steps, each of which contributes to the overall quality and functionality of the final product. The typical production process includes:

1. Weaving: The first step in FIBC bag production is the weaving of the polypropylene or polyethylene fabric. This involves the interlacing of warp and weft yarns on a loom to create a strong, flexible fabric with the desired dimensions.

2. Cutting and Printing: Once the fabric is woven, it is cut into panels of the appropriate size for the FIBC bags. These panels may then undergo printing to add labels, handling instructions, or company logos as required.

3. Sewing: The cut panels are then sewn together using industrial sewing machines equipped with heavy-duty threads. This step involves the assembly of the main body of the FIBC bag, as well as the attachment of filling and discharge spouts, lifting loops, and other accessories.

4. Quality Control: Throughout the production process, rigorous quality control measures are implemented to ensure that the FIBC bags meet industry standards for strength, safety, and performance. This may involve testing the fabric for tensile strength, conducting seam strength tests, and inspecting the finished bags for any defects or irregularities.

5. Optional Features: Depending on the specific requirements of the end user, additional features such as liners, baffles, sift-proof seams, or specialized closures may be incorporated into the design of the FIBC bags.

Quality Control Measures

Quality control is a critical aspect of FIBC bag manufacturing, as these containers are often used to transport valuable or hazardous materials. To ensure that FIBC bags meet the highest standards of quality and safety, manufacturers may implement the following measures:

1. ISO Certification: Many FIBC bag manufacturers adhere to international quality management standards such as ISO 9001 to demonstrate their commitment to producing consistently high-quality products.

2. Testing and Certification: FIBC bags may undergo testing by independent third-party organizations to verify their compliance with industry regulations and standards for safe usage and transportation.

3. Traceability: Manufacturers may implement systems to trace the origin of raw materials used in FIBC bag production, ensuring transparency and accountability throughout the supply chain.

4. Compliance with Regulations: FIBC bag manufacturers must adhere to relevant regulations and guidelines pertaining to the safe handling and transportation of specific types of materials, such as food products, pharmaceuticals, or hazardous chemicals.